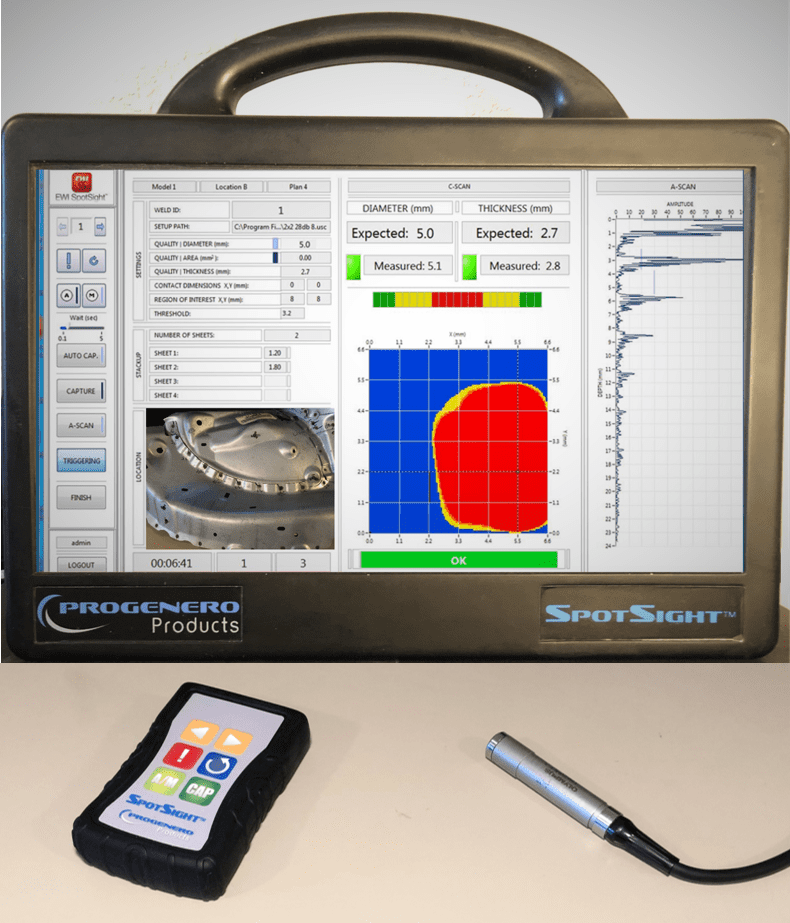

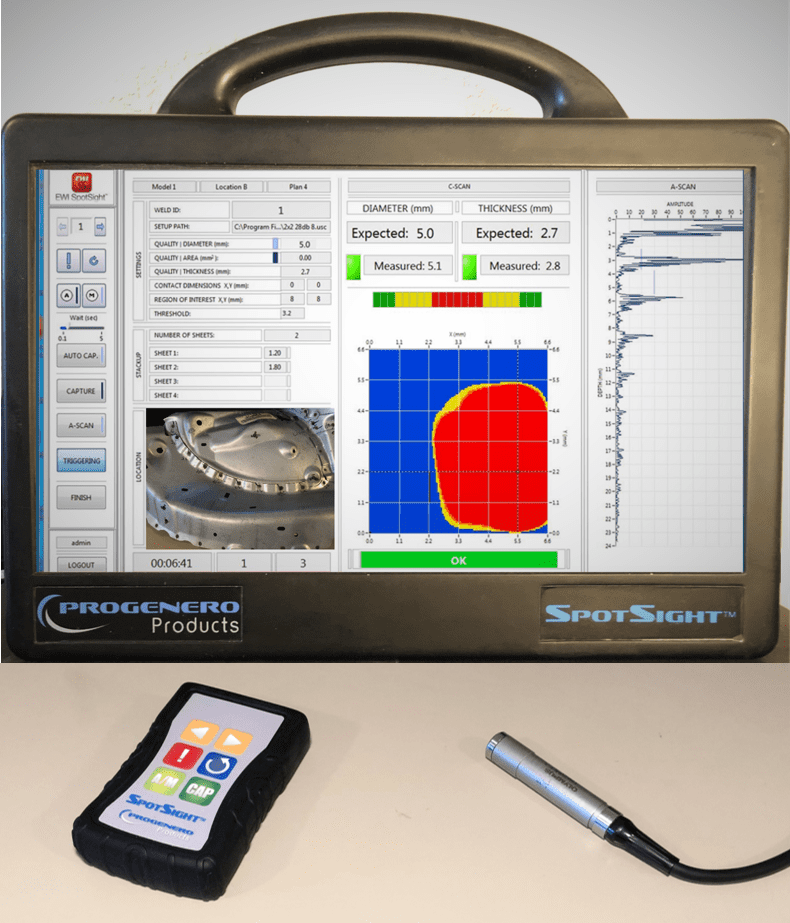

SpotSight has improved upon ultrasonic matrix phased array technology to provide the fastest and most accurate method of NDT for spot welds by harnessing the power of 3-D Matrix Phased Array ultrasonic technology. SpotSight determines the quality and effectiveness of welds by providing real-time A-Scan and C-scan imaging and comparing the results to predetermined specifications. Our unique 8 x 8 spherical ultrasonic array probe combined with advanced algorithms work together to provide the quickest, most accurate evaluation of a weld with dependable pass / fail results.