Accuracy, Speed, Flexibility

Most advanced Non-Destructive Testing (NDT) system for inspecting spot welds in the automotive industry.

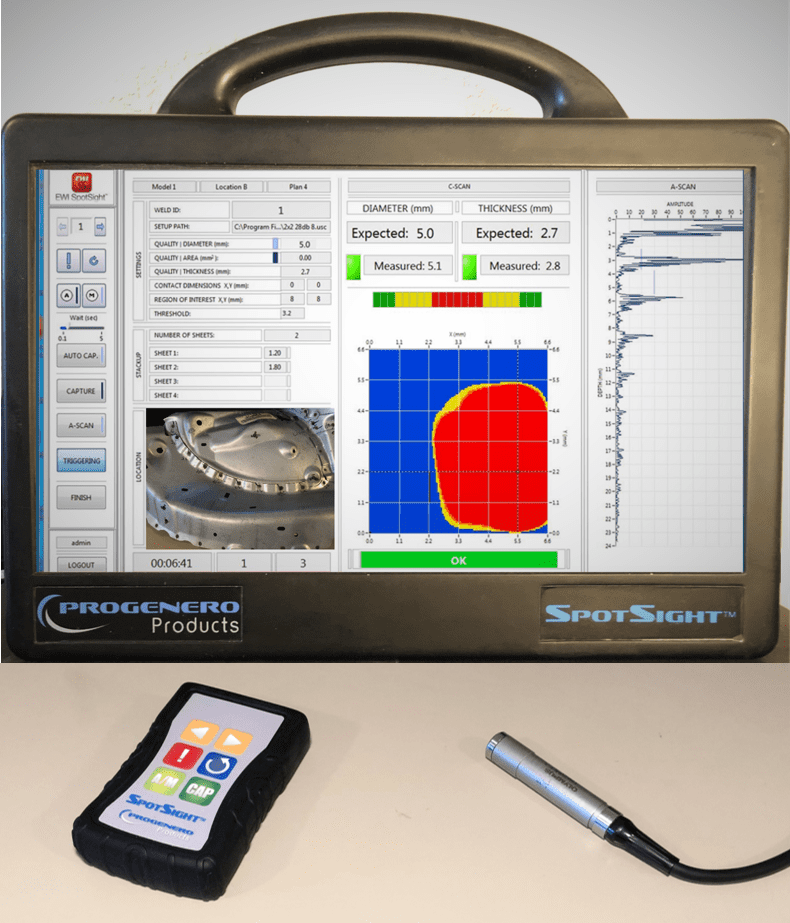

SpotSight harnesses the power of ultrasonic matrix phased array technology to provide the fastest and most accurate method of NDT for spot welds. SpotSight determines the quality and effectiveness of welds by providing real-time A-Scan and C-scan imaging and comparing the results to predetermined specifications. Our unique 8 x 8 spherical ultrasonic array probe combined with advanced algorithms work together to provide the quickest, most accurate evaluation of a weld with dependable pass / fail results.

Most Advanced NDT system available –

SpotSight stands alone:

– No Gel Couplant needed

– Minimal Training needed

– Fastest Processing

– Most Accurate Results