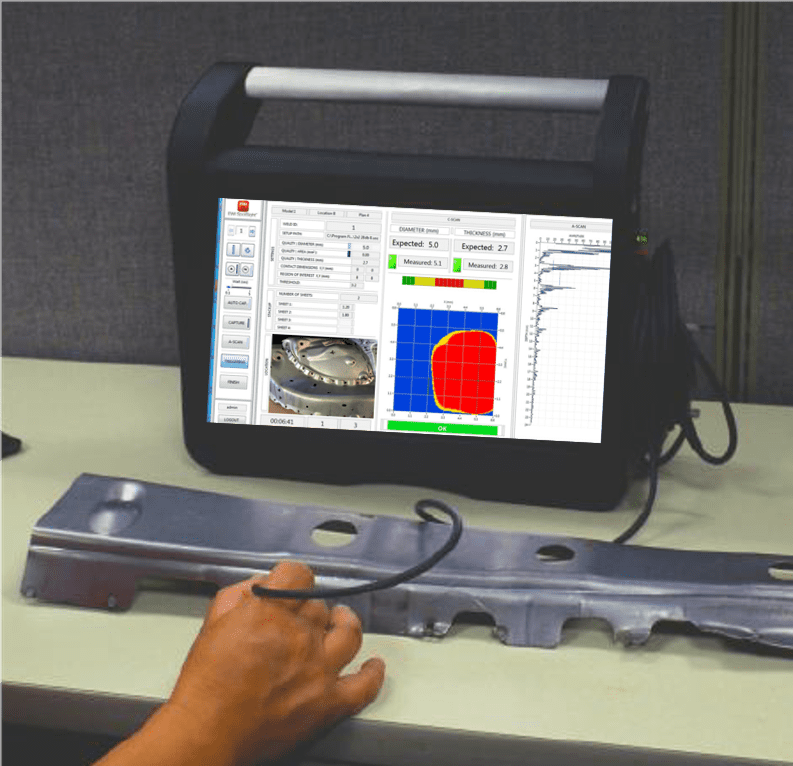

SpotSight is the most advanced system for:

Non-Destructive Evaluation (NDE) of the integrity of spot welds

Problems with many Ultrasonic testing systems

- Most systems require extensive training

- Many systems give inaccurate results

- Most systems require gel couplants, which are expensive and need to be cleaned off

SpotSight – best system for spot weld nugget inspection

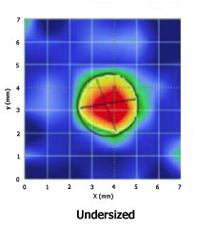

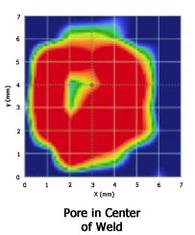

- High reliability eliminates false negatives

- Accurate Thickness readings

- Accurate Diameter readings

- High resolution 2D image

- Intuitive operation – minimum training

- Fast inspection – real time response

- Incorporates manufacturing based work flow

- No gel couplant needed to buy and cleanup

SpotSight Benefits

Training is quick and easy

- Users are operational in less than a day

- Easy-To-Use

Accurate

- Sizes weld nugget to + or -0.54mm with a 95% confidence level.

Fast

- Instantaneous Output

- Inspection Cycle in as little as 6 seconds

- Results can be recorded

NO Gel Couplant needed to buy or cleanup

- Simply use water as couplant

Well suited for automation

- see video of NDT automation with robot